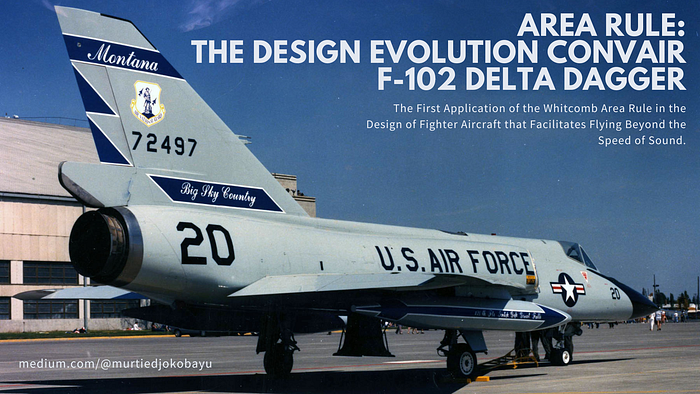

Area Rule: The Design Evolution Convair F-102 Delta Dagger

Second-generation fighter jets constitute the initial wave of fighter aircraft capable of reaching the speed of sound under operational conditions. The majority of early second-generation fighter jets have a maximum speed within the transonic speed regime (Mach 0.8–1.2). In this speed range, shock waves form around the aircraft, significantly amplifying drag and buffeting (vibration) experienced by the aircraft due to a drag type known as wave drag.

When flying in the transonic speed regime, first and second-generation fighter jets would experience severe vibration in the form of buffeting, along with a significant increase in drag. This increase in drag led to poor aerodynamic performance and slow acceleration for first and second-generation fighter jets when entering the transonic speed regime.

The drawback becomes problematic in both combat and non-combat situations. A low acceleration rate complicates interception missions, making them more challenging and costly. To attain their maximum speed, the aircraft’s engines must operate at their peak performance for an extended period, resulting in higher fuel consumption. The buffeting that occurs also diminishes the aircraft airframe’s lifespan and adversely affects on-board avionics and pilot ergonomics.

One of the “Century-series Fighter” aircraft in the United States Air Force facing this issue is the Convair F-102 Delta Dagger. The US Air Force expressed satisfaction with the performance of the YF-102 prototype during transonic regime flights. However, due to poor transonic aerodynamic performance, the YF-102 also struggled to surpass the speed of sound. The buffeting that occurred became intolerable for both the avionics components and the aircraft’s pilot. The worsening buffeting led to a crash of a YF-102 prototype from Edwards Air Force Base, injuring its pilot, Richard L. Johnson, who was also the head test pilot for Convair. Notably, Convair had initially promised that the F-102 design could achieve a speed of Mach 1.2. Due to these challenges, the YF-102 program faced the threat of cancellation.

Convair was exploring various solutions to address the problem. One solution that Convair focused on was applying the Whitcomb Area Rule to the YF-102 design.

In 1952, a NACA engineer named Richard Whitcomb discovered a phenomenon that correlated the cross-sectional area of an aircraft with the magnitude of the resulting drag force. Richard Whitcomb then created a rule of thumb named after him — the Whitcomb Area Rule. The Whitcomb Area Rule states that:

“two airplanes with the same longitudinal cross-sectional area distribution have the same wave drag, independent of how the area is distributed laterally (i.e. in the fuselage or in the wing).”

Moreover, it also states that:

“The wave drag of any body at transonic/supersonic condition is solely dependent on the cross-sectional area distribution of that body”.

The rule tells us that a simple body of revolution that has the same distribution of cross-sectional area as a complex airplane produces the same wave drag.

The YF-102 design maintains a constant fuselage cross-sectional area from the nose to the tail. However, the cross-section referred to in the Whitcomb Area Rule encompasses other aircraft features beyond the fuselage, including the wings and empennage (tail). Due to the delta wing feature of the YF-102, in addition to the constant fuselage cross-sectional area, the overall cross-sectional area distribution of the YF-102 is much larger toward the tail of the aircraft. After evaluating this, Convair engineers identified the issues that contributed to the poor aerodynamic performance of the YF-102.

To address the cross-sectional area distribution issue, Convair made modifications in 1953 by thinning several sections of the YF-102 fuselage that were parallel to the wings. This modification led to the revised YF-102A design.

The new YF-102A design, incorporating the Whitcomb Area Rule, enabled the YF-102A to reach Mach 1.2 with ease and significantly reduce fuel consumption during interception missions. The US Air Force was satisfied with the revised design and formally adopted it into service in 1956 as the Convair F-102A “Delta Dagger.” The Delta Dagger played a substantial role in escort and night strike missions during the Vietnam War.

The development of the Delta Dagger did not end there. In response to a request from the US Air Force, Convair further optimized the F-102A design. This optimization resulted in the F-102B, which was subsequently developed into the F-106 “Delta Dart,” capable of reaching Mach 2.35.